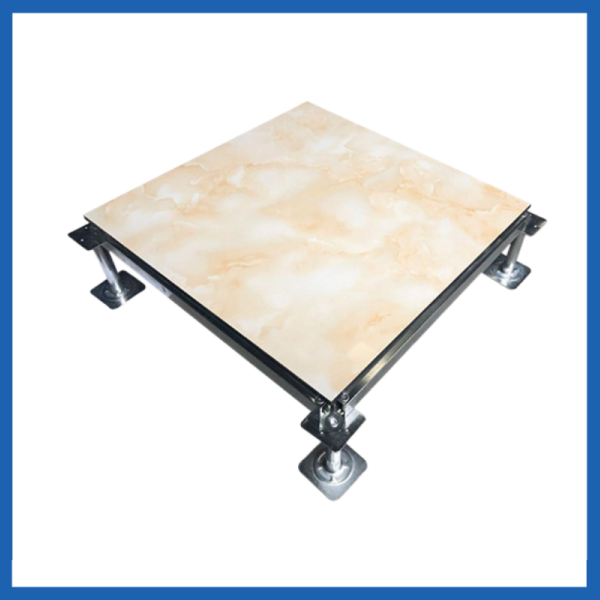

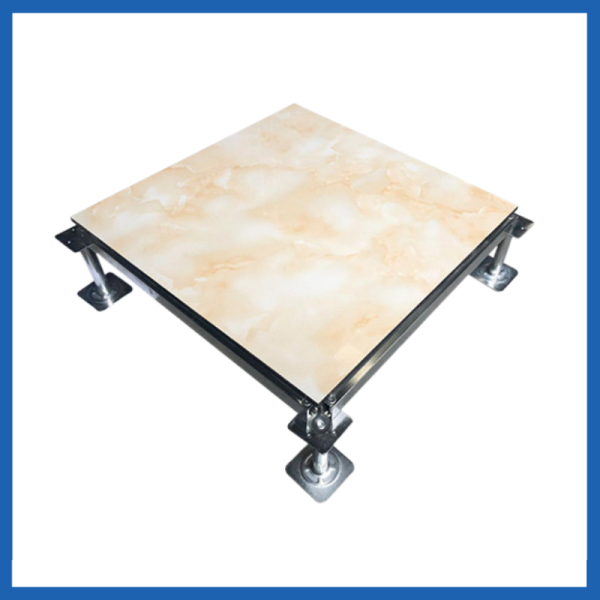

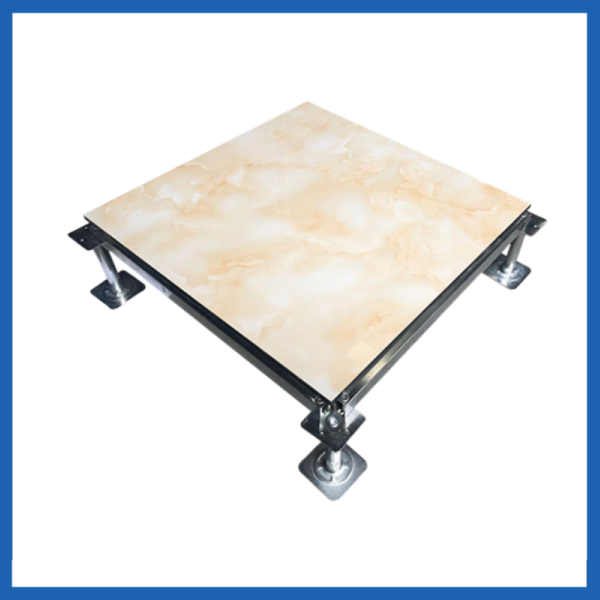

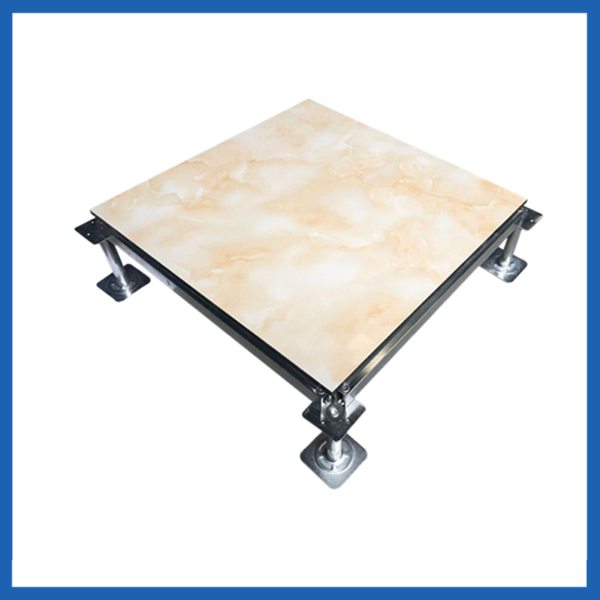

The conventional specification of vitrified tile ceramic raised floor is 602*602*40mm, and the surface thickness is 12mm marble. It is a new type of floor with fire prevention, wear resistance, cracking resistance, corrosion resistance and aging resistance. It has high bearing capacity and long service life. You can also customize the height according to your needs.

The vitrified tile ceramic overhead floor system is composed of floor, truss beam and support. The truss and its height adjustable support form a stable lower support system, and the floor is inlaid into the square enclosed by the truss.

Characteristics of vitrified tile ceramic raised floor: standardized floor components, high dimensional accuracy, easy construction and interchangeability. The high load structure design meets the erection completion level and is highly available on demand. The special height requires double-layer shockproof beams, and the steel structure and support mode can be designed. The color and material of surface materials shall be selected according to functional requirements. Moisture proof, rust proof, fireproof and durable.

Vitrified tile ceramic raised floor is generally used in places that do not need anti-static but need to be raised.

Beam: all steel floor supporting beam is divided into long beam and short beam. Specification of long beam: 21 × 30/32 × 1173mm, short beam specification: 21 × 30/32 × 573mm; The surface is galvanized and rust proof. The wall thickness of the beam can also be customized for places with different bearing capacity requirements.

Support: it is usually divided into standard support, reinforced support and super strong support. In addition, there are two special-purpose brackets: slope bracket and edge closing bracket.

Standard support: it is composed of upper support plate, screw, lock nut, support pipe and lower support plate, and the support pipe is generally 22 × 22mm square tube Φ 22mm round pipe, with galvanized surface, has good rust prevention and corrosion resistance.

Reinforced support: compared with the standard support, it has better bearing performance. The diameter of support pipe is usually Φ 25mm、 Φ 28mm、 Φ 32mm。

Super bracket: Mainly used in places where high requirements for load-carrying performance and overhead height are required. The diameter of the supporting pipe is Φ 38mm, Φ 45mm, Φ 73mm etc.

Slope bracket: Mainly used for making slopes.

Side-closing bracket: Mainly used for edge treatment of floors

Other ancillary accessories are diagonal brackets, horizontal pull bars and hoops as ancillary connectors of the brackets. Usually they are combined with extra-high and extra-strong brackets to enhance the stability of the floor installation structure. Screws, suction cups, wiring boxes, etc.

Widely used in electronic computer room, satellite ground station room, radio control room, TV transmitter control room, microwave communication station room, program-controlled switch room, clean factory, assembly workshop of electronic instrument factory, secret optical instrument manufacturing workshop, hospital, school and other occasions with anti-static requirements, large and medium computer room, communication room represented by switch, military and economic controlled by computer, National Security, Aeronautics, Space and Transportation.